Machine burnerThis situation, I believe everyone is not unfamiliar, some users even in the use of digital printing machine process also encountered this situation,sprayer It's a digital printing machineCore componentThe burning nozzle not only affects the normal printing of customer orders, but also is a waste of money. Therefore, we had better understand the knowledge of digital printing machine burner, and carry out effective evadeIn order to be effectiveImprove production efficiency .

Printing machine burning nozzle reasons:

01High voltage:

Digital printing machine has the best working voltage, once the working voltage is too high, the nozzle for a long time high load work, it is easy to lead to the rapid aging of the piezoelectric crystal, the phenomenon of burning the nozzle.

02Excessive static electricity:

Digital printing machineA large amount of static electricity will be generated during normal operation. If these static electricity cannot be guided out of the equipment in time, it is easy to cause damage to electronic components such as digital printing machine nozzle and circuit. Therefore, we must do a good job of digital printing machine anti-static measures, such as grounding wire, maintain Indoor humidity in40%-60%Between etc.

03Non-standard operation:

Digital printing machine do not frequently switch on and off the machine, each switch time interval is best5More than a minute. In addition, the nozzle of the digital printing machine in the case of unnecessary, try not to plug and pull the circuit, avoid the operation of the positive and negative pole of the power supply, and prevent the nozzle from being burned.

Finally, we should remind everyone that when using ink, we must pay attention not to drip onto the circuit board. Ink is a kind of ink withcorrosivityAfter the liquid sticks to the circuit board, it is easy to cause a short circuit, and then damage the nozzle.

How to prevent the nozzle from burning out:

one. Digital printing machine nozzle inInstall houroutageIf it is easy to break the nozzle in the energized state, gently push the car to move left and right after installation, detect whether it is smooth, and start with strong controllability, it means that the nozzle has been installed in place, and then it can be powered on.

Two, in the digital printing machineelectrifytemporally No ink Check again if there is no bad contact, otherwise the digital printing machine nozzle will burn out due to short circuit.

Third, the surface of the digital printing machine nozzle should have protective measures, do not collide, so as to avoid damage and deformation, affecting the normal operation of the digital printing machine.

At this time, you can add ink, the amount of ink, the ink pump, and the cleaning sheet.

first-installedDigital printing machineMost of the inside of the nozzle has air, so we must first print the picture sample to discharge the air, and then carry out normal printing work.

Do you understand the reasons why the printing machine nozzle burns out and how to avoid the method of nozzle burning out? If in doubt, you can leave a comment below the article; For additional machine maintenance tips or equipment information, you can also call Audley's service hotline:400-6179998; Or scan the QR code below:

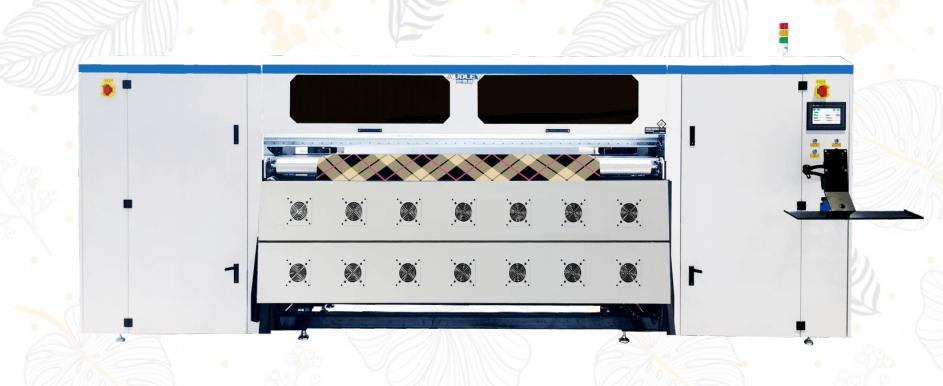

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.