After the start of summer, the summer season officially began, and the advertising industry ushered in a hot summer time. Temperatures are warming and thunderstorms are increasing across the country, especially in the south, where the annual plum rain season is approaching.

Drizzle 霪 drizzle, catalpa township paddy field fertilizer.![]()

Fish jump Batang May Mojin, warping welcome Duanyang plum.

Sparrow whisper dance, clear sprinkle willow silk bud.

Rivers overflow rivers full, Jiangnan Lin Lin Pei.

This is a proverb about Meiyu, verified by relevant regional meteorological data, accurate70%to80 %. It seems that this rainy season is inevitable. So, in the rainy season, we must do wellWide-format printer Moisture-proof matters.

Why pay attention to moisture-proof in rainy season?

When it rains, the first thing that changes is the humidity of the environment. In the south, the humidity on rainy days is generally80%Above, some areas can even reach95%Above, the north is about70%Around. The humidity requirements of the photo machine printing environment are in40% ~60%Between, the humidity is too large, will cause the printing material to be damp, ink viscosity becomes larger, thus affecting the print output screen, and even blocking the nozzle.

Plus, in a humid environment,Wide-format printerThe operation may also cause the motherboard to short circuit or even burn, and the picture printed in a humid environment is more difficult to dry than usual, so that the work efficiency is greatly reduced.

How to do moisture-proof in rainy season?

①The rainy season should pay attention to close the doors and Windows to prevent wet air into the room. If the weather gets better, you can open the window for air.

②Use the air conditioner to dehumidify. The dehumidification function of air conditioning is the use of the principle that the water in the air will be condensed into water when it is cold. However, since dehumidification is only an auxiliary function of air conditioning, the dehumidification effect is often not satisfactory. In order to avoid excessive humidity, it is recommended that you can place some desiccant and so on.

③In order to make the print screen dry as soon as possible, remind everyone not to roll before the screen is not dry, otherwise the ink will be smudged and adhered to, which will lead to the screen printed out directly scrapped. It is recommended that you open the external drying system of the photo machine or appropriately slow down the printing speed to shorten the drying time.

④Before starting the machine every day, be sure to use a hair dryer to blow the motherboard, the small car board and the socket of the data cable at both ends5~10Minutes, keep the board dry, so as to reduce the impact of moisture, to avoid the nozzle vertical line, shielding and spray holes do not ink phenomenon.

⑤The printing medium is easy to absorb water and get damp, so we must pay attention to the storage method of the printing medium. Put the printing material back into the original packaging after each use, try not to touch the ground and walls, it is best to put on the shelf, or on the ground cloth.

What happens when the tide turns?

When we find that the photo machine board is damp, we should not continue to turn on the machine as usual, what we need to do is to remove the board from the machine, and then dry it, and then check whether the functions are normal after drying, and make sure that there is no safety risk before use.

The maintenance of the photo machine in a humid environment is of great benefit to extending the life of the equipment, and can avoid quality problems in the output screen.

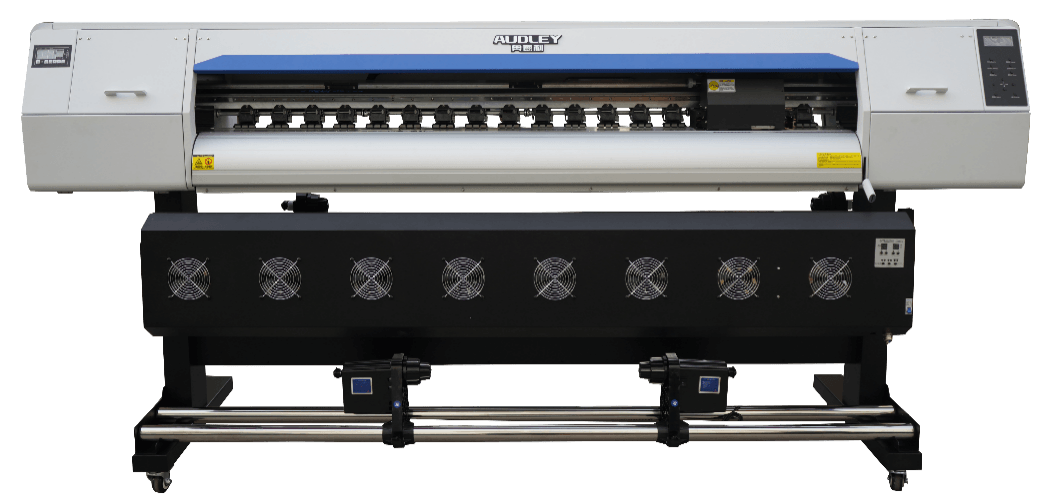

Leading the industry trend, show the style of India-The Audley photo machine

How do you understand moisture-proof maintenance of photo machine? If in doubt or if the problem is seriousLeave a comment below; You can also call Audley's service hotline:400-6179998; Scan the QR code below:

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.