UVThe machine is the same as other machines and equipment, there are many different models, there are also special precautions and maintenance guidelines for the operation, we need to strictly follow the operating steps to use, otherwise it is easy to cause machine failure. Then in useU VmachineWhat should I pay attention to at work? How should I maintain it? Let's take a look at my share!

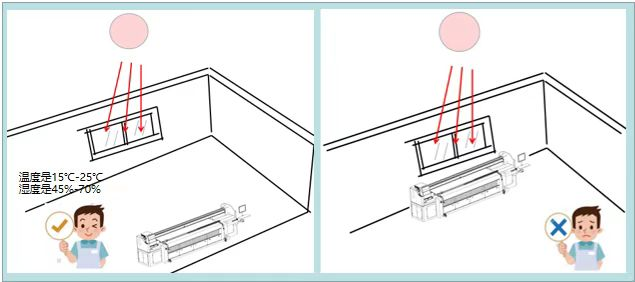

Schematic drawing

Machine use precautions

The normal indoor temperature is controlled at20-25Degree, humidity control at55-65%About (The indoor temperature is easy to makeU VThe machine appears floating ink, loose ink, bidirectional line pairs, dislocation and other phenomena.)

Before starting:

①Inspection of critical components. The bearing, guide bar and other components should be inspected and lubricated to reduce the resistance of equipment operation and ensure the normal operation of printing work.

②Do a good job cleaning. Check the printhead, grating, guide bar, etc., these parts are easy to accumulate dust and ink, and timely cleaning can ensure the clarity of the printed image.

③Do a good job of checking. InspectUVWhether the printer lines are connected properly, whether the ink is enough for the next work, whether there is waste ink,UVIs it normal after the light is turned on? If there is an anomaly, make adjustments in time.

④Calibration and testing. Calibrate before startingUVThe position of the printer and the printing test are carried out at the same time to see whether the printing effect meets the requirements. If it does not meet the requirements, it needs to be adjusted.

Printing process:

①Adjust the height.UVWhen adjusting the height of the flatbed printer, there will be infrared detection of the height of the object, but the product should be placed and placed flat

②Must be maintained during printingUVThe printer's mask disc is always closed.

③towardsUVWhen the coil is printed, the material is placed in the middle of the conveyor belt as far as possible, which is conducive to the balance of the conveyor belt.

④It is strictly forbidden to cut the material on the surface of the conveyor belt with a knife, which may cause the risk of damaging the conveyor belt.

Four. Keep the body clean, do not stack other items on the equipment, so as not to fall into the running machine, affecting the work.

Five. The machine is as clean as possible in the environment, Run in an environment with less dust, which is to prevent dust and other foreign objects from falling onto the axle, grating or components, resulting inUVThe printer is not working properly.

(Note: lifting screw,XGuide rail,YGuide rail,YScrew, clean up, evenly apply a small amount of lubricating oil or grease)

Machine maintenance

one Temperature control: to place in a cool, backlit corner, avoid high temperature and direct sunlight.

two Power off moisturizing: such asUVIf you do not work for a long time, you can choose to power off and moisturize, do not leave the machine in a standby state, increasing power consumption and damage.

Three. After starting, print the test strip first. Check whether the nozzle is blocked. Summer temperature is too high, prone to ink dry situation, if the printed test strip appears broken, wire drawing phenomenon, need to clean the nozzle.

UVprinterHow to maintain, use need to pay attention to what you understand? If in doubt, you can leave a comment below the article; For more information about the equipment, you can also call Audley Service hotline:400-6179998. You can also scan the QR code below:

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

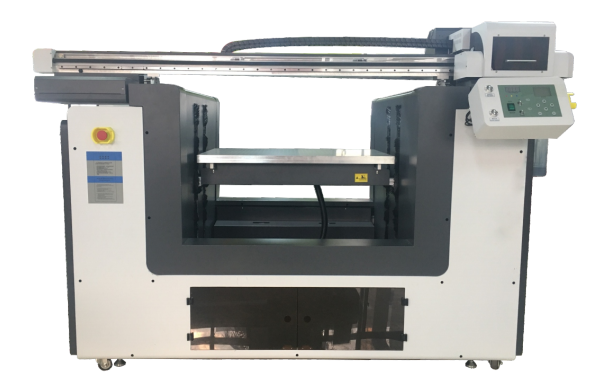

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.