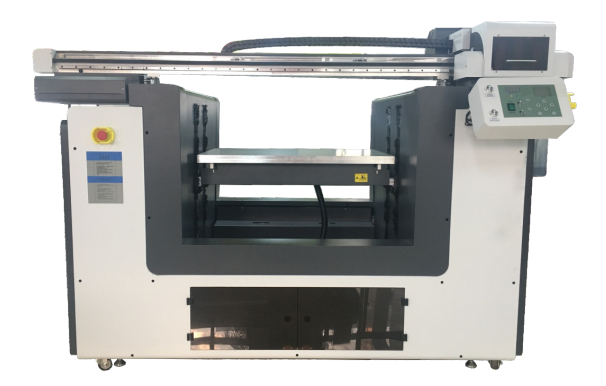

UVprinterIn the course of daily use, it will inevitably appearUVprinterPrinting blank, broken ink, pattern light and other problems, each problem will affect the user's efficiency and cost, how to solve these failures? Find a professional maintenance personnel to repair, but some small problems we can solve ourselves. Here to tell you the common faults and solutions!

Common faults and solutions:

01 UVPrinter print blank:

UVThe printer does not print ink in the printing, printing blank, most of this failure is due to the blockage of the nozzle or the ink inside the cartridge is exhausted.

Solution: If the ink runs out, this is easy to solve, just replace the ink cartridge and add new ink. If there is a lot of ink, but there is a blank print, it may be the nozzle is blocked, and the nozzle needs to be cleaned. After the nozzle cleaning is completed, if there is still a failure, it is necessary to consider whether the nozzle is broken, which requires the manufacturer to consult.

02 UVPrinter out of ink:

In the process of printing pattern, individual nozzles do not produce ink. The reason is that the nozzle channel is blocked, the nozzle operating voltage is set improperly, the ink sac is blocked, the ink problem, and the negative pressure adjustment is improper.

Solution: ink pressing, cleaning liquid flush the spray hole, adjust the working voltage of the nozzle, soak and ultrasonic cleaning the nozzle, replace the high-quality ink, adjust the appropriate negative pressure value.

03 UVPrinter print pattern is light:

UVThe color of the pattern printed by the printer may be due to dry ink, the wrong type of ink, the intake of air in the ink tube, the high operating temperature of the printer and the blockage of the nozzle.

Solution: If it is the ink problem, just replace the ink. If it is an ink-tube intake, it is necessary to discharge the air before working. ifUVIf the working time of the printer is too long and the working temperature of the printer is too high, we need to suspend the work for a period of time and wait for the temperature to drop after the work. If the nozzle is blocked, we need to clean the nozzle.

04The ink falls off after the printer finishes printing:

This can happen because of the wrong coating, direct spraying of the printed material without cleaning, or starting the printing work before the coating is completely dry.

Solution: Clean the print material before spraying or allow the coating to dry completely before printing to avoid ink loss problems.

05 UVPrinter garbled code:

Phenomenon: The picture appears irregular spray

Causes: inkjet data transmission processing error, small car board failure, data line loose or fault, optical fiber failure,PCICard failure, screen processing problems.

Solution: Arrange sprinkler heads to test individual sprinkler heads one by one, troubleshoot sprinkler heads, and replace data lines(Sprinkler data line or small car plate data line)Replace the small car plate/Optical fiber/PCICard, reload screen for processing.

06Universal printer nozzle can not move:

Cause: The machine is offline; sprayer(trolley)Servo motor offline.

Solution: Press the green switch to connect the computer and printer; Turn off the machine,10Restart in seconds to reset the motor.

UVFlatbed printerDo you understand the common faults and solutions? If you have questions, you can leave a comment below the article, or call Audley's service hotline for more information about other devices:400-6179998.Or scan the QR code below:

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.