Due to the cold weather, the indoor temperature is lower, and the viscosity of inkjet printer ink becomes higher. Henan Indu small edition suggestion: photo machine/UVFollow the following steps to operate the device.

1.The inkjet printer room must be installed with air conditioning and other warm equipment, open in advance, until the indoor temperature reaches20CWhen the above device is turned on, the temperature display of the secondary cartridge is reached40°Above, can press ink cleaning nozzle. Only when the temperature of the nozzle and the temperature of the secondary ink cartridge reach the normal setting temperature can you print.

2.In winter, the room is dry and prone to static electricity. Please keep the indoor humidity. Indoor humidity can be guaranteed by indoor mopping and equipped with a large capacity humidifier. To avoid printing problems caused by indoor drying, such as flying ink, broken ink, bidirectional uneven printing.

3.LEDThe water cooler must be replaced with antifreeze to prevent water flow from freezing due to weatherLEDLamp work, resulting in print ink dry, damageLEDA lamp bead.

4.Because the dry winter is easy to generate static electricity, please remove the flocculum adsorbed around the sprinkler bottom plate due to static electricity in time. Avoid oblique spray or plugging due to flocs sticking to the nozzle surface.

5.Due to the thermal expansion and contraction characteristics of the soft film, be sure to check the length of the print. You can modify the length compensation to ensure that the printed material meets the requirements.

Please maintain your equipment correctly. If you have any technical problems, please contact the technical personnel in time!

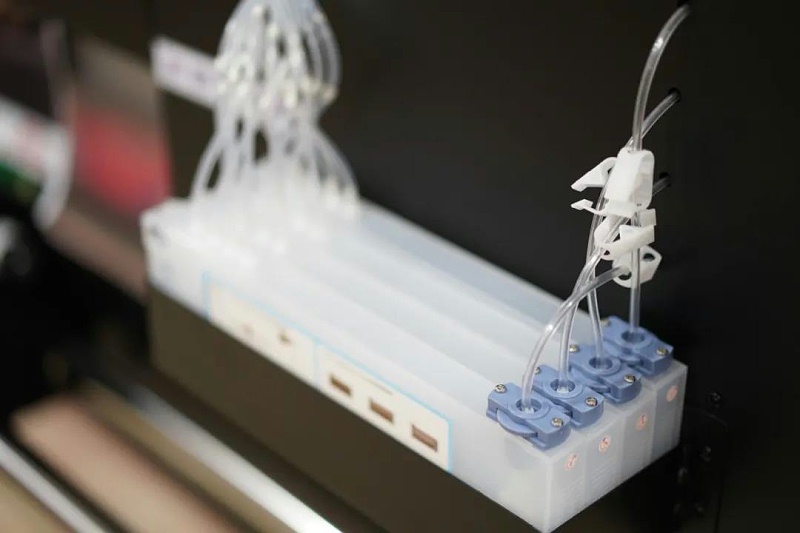

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.