Digital printing machineThe service life is a more concerned issue in the printing industry, and the maintenance of the digital printing machine nozzle is an important link to extend the service life of the machine. The good and bad maintenance of the nozzle not only directly affects the service life of the digital printing machine but also the key to reducing the cost of warranty costs.

How to extend the service life of digital printing machine, digital printing machine nozzle in use What are the main causes of the failure? How to clean the nozzle after use? What should I pay attention to? In view of this series of problems the following article for everyone to solve the confusion.

Tips for sprinkler use:

①In the case of not turning off the power switch and cutting off the total power supply, do not arbitrarily install and disassemble the circuit of the digital printing machine, otherwise it will damage the service life of each system and harm the nozzle .

②Whether replacing or fine-tuning the nozzle in use, do not use brute force, and replace or fine-tuning the nozzle according to the specifications of the equipment user manual.

③In the process of use, do not mix the two different configurations of ink, the proportion of different ink configuration raw materials will be different, the mixed use of two different inks will change the color and quality of the ink, the quality of the ink will directly affect the printing effect, and even lead to blockage of the nozzle.

④Do not remove the nozzle from the digital printing machine and place it alone, especially in dusty places. Because the water contained in the ink will gradually evaporate, drying the ink will cause the nozzle to block. If the nozzle is blocked, it should be cleaned before use.

⑤The nozzle cleaning solution is corrosive to some extent. When cleaning the nozzle with the cleaning solution, you are advised to take an appropriate amount of the cleaning solution and import it to the nozzle for cleaning.

Sprinkler failure cause:

①When spraying the spray hole to the fabric, there will always be some ink around, and this part of ink will gradually make the spray hole smaller or even block the spray hole after drying in the air.

②If the nozzle is used for a long time, the ink will not flow in the nozzle for a long time, and it is easy to adsorb on the internal filter or the wall of the ink channel, so that the cross-sectional area of the ink flow will become smaller, and the ink will not flow in the nozzle.

③If the nozzle is not protected when the ink is replaced, it will also affect the inkjet state of the nozzle.

④The nozzle is removed from the printer and placed separately, especially in dusty places, the water contained in the ink will gradually evaporate, and drying the ink will cause the nozzle to block. If the nozzle is blocked, it should be cleaned before use.

Tips for cleaning sprinkler head:

①When cleaning, a thin rubber hose can be placed in the front end of the medical syringe and loaded with a strictly filtered cleaning solution for washing. When rinsing, use a magnifying glass to carefully observe the spray hole. If there is a silted residue near the spray hole, it can be removed with a soft rubber product. The integrated printing head that has been unused for a long time is blocked by the drying of ink and can be cleaned after being soaked in hot water.

②Do not use sharp objects to clean the nozzle, do not hit the nozzle, do not touch the nozzle with your hands.

③Do not disassemble or install the sprinkler head in a live state. Do not touch the electrical contact on the sprinkler head with your hands or other objects.

④Do not remove the nozzle from the digital printing machine and place it separately, and do not place the nozzle in a dusty place.

Digital printing machineHow to maintain the nozzle, how to clean it, what do you need to pay attention to when using it? If in doubt, you can leave a comment below the article; For more information about the equipment, you can also call Audley Service hotline:400-6179998. You can also scan the QR code below:

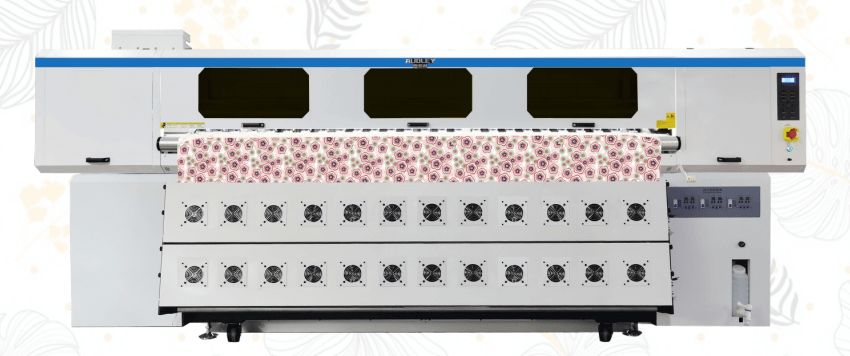

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.