The weather is gradually getting warmer, everyone's dress is gradually bright and lively, and you can arbitrarily choose a variety of skirts to wear, which is undoubtedly beautiful and pleasant for girls who love to wear skirts. So do you know how these beautiful and stylish dresses are printed?

There are many ways to print patterns on clothes: screen printing, thermal transfer, digital direct injection, etc. Different printing technologies and methods will have different effects. Today we mainly introduce isPrinting machineThe way of heat transfer.

The main principle of heat transfer flower:

The ink on the paper is sublimated to the cloth by high temperature and high pressure. It is mainly used for synthetic fiber fabrics such as polyester, polyamide and blends. Pure cotton fabrics are not suitable for thermal sublimation, because pure cotton fabrics do not absorb ink. And when the temperature is high, the temperature has a great impact on the cotton cloth surface, not only the color of the cloth surface, but also the shrinkage and so on.

Main advantages of heat transfer flower:

![]() It can print the wheel gallery especially fine patterns. The pattern level is rich and colorful, the shape is realistic, and the artistry is high, which is unmatched by the general direct printing method.

It can print the wheel gallery especially fine patterns. The pattern level is rich and colorful, the shape is realistic, and the artistry is high, which is unmatched by the general direct printing method.

![]() Suitable for large shrinkage, easy to deform fabrics: such as knitted fabrics or synthetic fiber deformable silk fabrics.

Suitable for large shrinkage, easy to deform fabrics: such as knitted fabrics or synthetic fiber deformable silk fabrics.

![]() The printing technology integrates green, environmental protection, low-carbon, energy saving, emission reduction, ecology and so on. And after printing fabric, feel soft, bright colors, rich layers, good permeability.

The printing technology integrates green, environmental protection, low-carbon, energy saving, emission reduction, ecology and so on. And after printing fabric, feel soft, bright colors, rich layers, good permeability.

![]() The equipment investment is less, the operation is simple and convenient, the genuine product rate is high, the production turnover is fast, and the requirements for fabric pretreatment are relatively low.

The equipment investment is less, the operation is simple and convenient, the genuine product rate is high, the production turnover is fast, and the requirements for fabric pretreatment are relatively low.

With the development of digital printing, heat transfer printing is becoming more and more popular. The high precision and high quality of digital printing determines its high requirements for digital printing equipment. Audley launched a variety of digital printing equipment,One of the most popular AudleyF 2015Industrial printing machine.

Its collocation15An EpsonI3200-A1Nozzle, high efficiency, low cost, high precision to create excellent printing quality, ultra-cost-effective to meet the needs of fast printing and high-end custom design.

Epsoni3200-A1

F2015Industrial printing machineAdvantages and features:

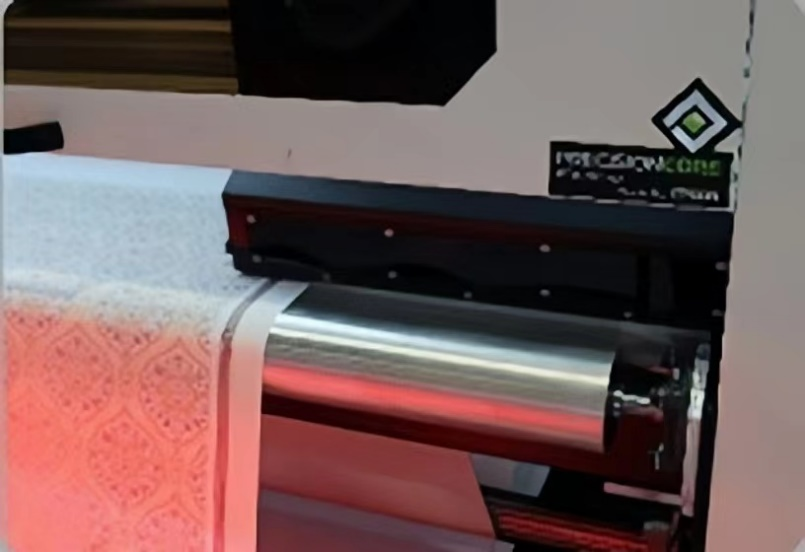

①Using no pressure wheel, rubber roller type paper, more suitable for thin paper printing, paper more stable.

②TFPThin-film piezoelectric technology+2.5plVariable point ink drop function, accurate positioning of ink drop, image color level is richer and fuller, printing effect is more exquisite.

③Inflatable shaft rewinding system: automatically adjusts the air pressure. So that the force is uniform, so that the paper is more flat. It has the characteristics of large bearing weight, long service life, uniform loading and receiving of paper, and short inflating and deflating operation time.

④Easy to achieve any pattern, high-precision printing photos, vivid patterns, highlighting personality.

Henan Indu with advanced printing technology, in order to achieve high-quality production needs, but also to meet the small and medium enterprises to control the cost of printing production, for the digital printing industry to bring more printing wonderful.

Printing machineDo you understand the unique heat transfer technology? If in doubt, you can leave a comment below the article; If you want to know more about the printing machine, you can call the Audley service hotline:400-6179998 You can also scan the QR code below:

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.