Everybody knowsuvFlatbed printers are made up of various parts, One of the very core parts is the flatbed printer nozzle,And on the marketuvFlat machine nozzle brand and variety are also wide We're Audley'sU VThe machine nozzle is Ricoh nozzle and Epson nozzle. Today, Xiaobian will explain the maintenance and maintenance of Ricoh nozzle.

Act as2019Ricoh gives you a bombshell in the inkjet industry, igniting the inkjet industry to a higher level, RicohG6The nozzle is a new out of the nozzle, each douvPrinter manufacturers want to quickly import this nozzle, for as soon as possible to make their own RicohG6Nozzle machine, unfortunately, the R & D data parameters in this area are relatively few, to be matched to the board, ink, software are developed and tested. Although in2019Ricoh has been launched in the past yearG6Sprinkler machine, but many places and details still need to be improved, the industry conservative that RicohG6The machine should be stable and mature202 2This year.

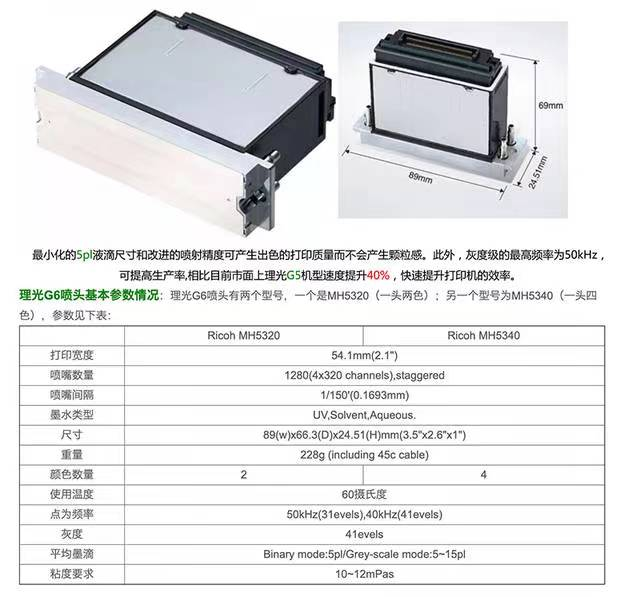

Ricohg6Nozzle R & D data parameters are relatively few,Only some information about Ricoh can be provided hereG6Some parameters of the nozzle are in condition ,Hope to be helpful to those R&D technicians. RicohG6Two types of sprinkler ,One isMH5320(One head with two colors)The other one isMH5340(One head with four colors) , All with the finest drops of ink5pl.Can apply to a variety of water-based ink, weak solvent ink,uvInk, textile ink and other inks, customers can also freely choose a head of two colors or a head of four colors according to the need, the more colors selected, the corresponding speed and accuracy will decline, the use of long and short connection lines. Product composition MH5320(1First two colors) MH5340 (1First four colours) MH532020C (Length: 195mm) MH5320 45C (Length: 453mm)

Among them:

1When using color:150dpi×4column/color→600dpi

2When using color:150dpi×2column/color→300dpi

4When using color:150dpi×1column/color→150dpi

:RicohMH5320/5340Nozzle product positioning : Jet flow=Nozzle number×Number of holes×Ignition frequency,Gen6-MH5320/5340sprayerMainly for industrial high-speeduvThe field of printing.

RicohMH5320/5340Three characteristics of sprinkler

1.High productivity

Firing frequency boost→The amount of ink spit per unit time is increased MH5420

Single-stage grayscale print mode:30Khz

Multilevel grayscale printing mode:20Khz MH5320

Multilevel printing in grayscale:50KhzHalf the time in the same resolution mode

Example:600x1200dpiMap making Car scanning speed Ignition frequency PassThe number MH5320option 1.5m/s 35.4Khz 4(x1;y4) MH5420option 1.4m/s 17Khz 8(x2;y4) Increase ignition frequency, reducePassNumber, to achieve the same drawing quality. Reduce the requirement of car speed improvement and reduce the difficulty of car control design.

2.High precision

Supports multi-level grayscale printing For different application scenarios Provide an optimized visual experience For close-ups, select droplet printing; For a long view, choose large drop printing; For daily use, mix large and small drops.

3.High ink compatibility

MH5420/5440 UV/solvent

MH5421/5441 water-based

MH5320/5340 Parameter comparison

Nozzle characteristics:

MH5320/5340MH5420/5440 MH5421/5441

Print width54.1mm54.1mm

Nozzle number1280(4 x 320 )1280(4 x 320 )

Resolution600dpi600dpi

Compatible inkUV, water, solvent

MH5420/5440:uv, solvent MH5421/5441: Water-based Color quantity44

Ignition frequency50Khz30Khz

Droplet size5-15PL 7-21PL

Viscosity range10-12mPa/s10-12mPa/s The cable can be inserted and fixed.

uvPrinters need regular maintenance and maintenance for the nozzle, pay attention to the proper maintenance of the nozzle, which is the best way to maintain the best work of the nozzle, but also to preventuvPrinter nozzle blockage is the main means. If maintenance is neglected, asuvOne of the core components of the flatbed printer, replacing a nozzle can cost tens of thousands. Therefore, a new sprinkler needs to reiterate the method that has been maintained;

Sometimes the nozzle is blocked and cannot be inked, and we only need to clean it simply to make it intact as before.The following points are for reference only:

First, maintenance of the equipment nozzle,In order to make the nozzle in the best working state, before the equipment is officially put into operation, play as many pictures as possible or test the state of the nozzle to see whether the state color is complete, there is no broken ink phenomenon, and when the color is broken, it means that the nozzle is blocked. Need to press ink or clean the nozzle.

Second, how to maintain the sprinkler after the completion of the work every day.

After completing all the printing tasks, the maintenance of the sprinkler head only needs to be finished before shutting down every day, spread the finished dust-free cloth on the moisturizing pad and drop some moisturizing liquid. If the machine is equipped with moisturizing pad, directly put the moisturizing liquid drop on the moisturizing pad.

Third, the treatment method after finding a slight blockage of the nozzle:

1, routine cleaning:No matter when a little blockage of the nozzle is found, it is necessary to press the stop without hesitation. After printing, use a manual pumping pad or negative pressure to spray the ink from the nozzle for nozzle cleaning. Finally, spray some cleaning liquid on the surface of the nozzle with a plastic extrusion bottle to wash away the residual ink.

2Easy cleaning:Use special cleaning liquid or alcohol to clean the nozzle and clear the blocked or oblique spray hole;Note that it is best to use the cleaning liquid cleaning function of the standard on the machine, if not, you can manually inject the cleaning through the syringe, and the intensity should be controlled50KPAWithin.

3 Medium cleaning method:Use the second step simple cleaning method to clean the nozzle, and then stick the non-woven cloth with cleaning liquid on the surface of the nozzle and place it12-24Hour (s).

4, deep cleaning method:Use the second step of simple cleaning method to clean the nozzle, and the surface of the nozzle is also cleaned, and then slightly back pumping through the syringe, repeated several times until the cleaning solution is injected, until all the spray holes are sprayed normally.

5, heavy blockage,Need to remove the nozzle, sent to the company professional cleaning. The repair success rate for serious failures is only40-50%

Fourth, the treatment method of frequent blockage of the sprinkler is found in the process of inkjet painting:

1 First press stop inkjet operation,Move the nose to the leftmost cleaning position. All computers and equipment should be turned off, and the nozzle should be emptied of ink and cleaned with a special cleaning solution.

2 , disconnect the nozzle from the ink supply system,Remove the ink supply sac on the nozzle, and then use a glass syringe to extract special cleaning liquid to clean the nozzle, method: each use 40ml Cleaning solution, every interval 10 Once a minute, total 3 ~ 4 Time.

3 By positive pressure ink, the ink in the entire ink supply system is emptied.The ink in the entire ink supply system is cleaned with a special cleaning solution;

4 Replace the filter, inject new ink, and connect the nozzle.

Fifth, the above treatment method is not effective or temporarily no effect when the treatment method:

1 ,Remove the nozzle from the nozzle tray.

2 ,In a clean glass container ( For example: beakers ) Pour proper amount of special cleaning liquid into the nozzle to flood the bottom of the nozzle 2 ~ 3mm To be appropriate, be sure not to bubble to the main board of the nozzle, bubble10Every minute, use a syringe to draw the cleaning solution and rinse against the spray hole, repeatedly2Time.

Look out : The motherboard inside the nozzle must not contact the cleaning solution, otherwise it will damage the nozzle. Be sure to strictly control the time to prevent damage to the nozzle, and be sure to pay attention to the continuous use of the cleaner to clean not more than three times.

3,Extract with a glass syringe40MLThe cleaning liquid of the nozzle is cleaned, and only when the water is in a straight line state can the cleaning be effective, and the nozzle can continue to be used.

Six, the equipment is expected to 48 Treatment method when not in use for more than one hour

If the equipment is expected to 48 Do not use for more than an hour, the ink in the nozzle must be cleaned, otherwise the ink in the nozzle will dry because the ink gradually volatilizes,Serious damage to the nozzle can even be irreversible. The treatment method is as follows:

1 ,Turn off the power to the inkjet.

2 ,Move the head to the leftmost cleaning position and place a corrosion resistant container under the nozzle to hold the cleaning liquid waste.

3 ,Remove the nozzle, use a syringe to flush out the ink in the nozzle, and then wash the nozzle with a special moisturizer. Because the residual cleaning solution left inside the nozzle will corrode the nozzle, it is necessary to use moisturizing solution last.

4,Place the cleaned nozzle in a dry corrosion-resistant container and seal it, especially for placement1If you are older than a month, seal it well to prevent the moisturizer from drying out.

If you have any questions, you can leave a comment below or call Audley's helpline:400-6179998 You can also open Alibaba on your phoneAPPsearchHenan Indu digital super factory,Various products, more concessions, waiting for you to buy!

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.