Under the influence of market demand, digital printing has further flourished, for the traditional inefficient screen printing process, digital printing no matter from the intelligent variety, industrial customization, high precision and high-speed characteristics, for the clothing textile industry to bring new impetus, promote the development of the entire printing industry. In this market background, Kingdee accumulates research and development of printing equipmentEfficient and stable, continuous investment in capital and research and development concepts, production toF3Digital printing machine based on new printing equipment, and hot stamping film based on hot stampingprinter&Shake powder machine, each unique process and design concept, for printing people to bring new ideas!

Since Kingdee printing machine was put into the market, with excellent printing quality, high-speed and high-precision printing effect, it has been loved and trusted by printing people, and is now a clear stream of digital printing equipment, which has brought high value to many people in the industry.

Kingdee series printing equipment

Factory workshop

KingdeeF3Hot film function highlights

1.Lack of ink alarm function to achieve unattended;

2Reisai brushless motor, higher precision, more stable performance;

3Intelligent ink shortage reminder to ensure the continuity of printing work;

4The use of international high-end software, more realistic drawing, better reducibility;

5Intelligent drying system, energy saving and emission reduction, start with the equipment working face;

6Equipped with advanced intelligent nozzle cleaning and moisturizing device, operation and maintenance is more convenient;

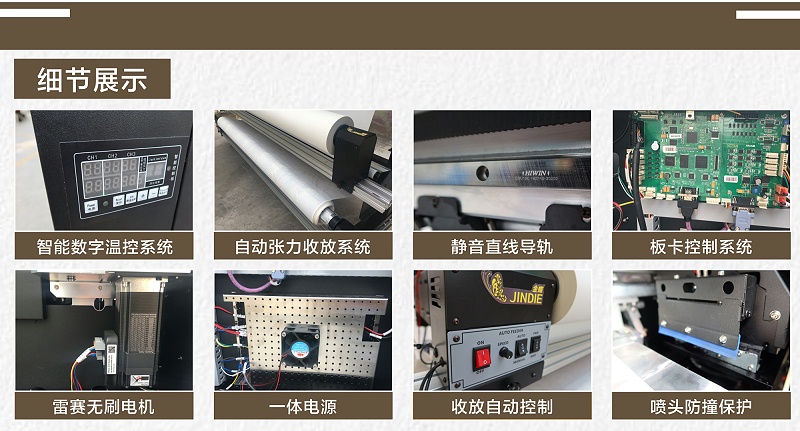

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.