The smoothness of the ink path system of the photo machine is the premise of normal printing, and the ink cartridge is an important part of the connected supply device, which directly affects the test and printing effect. When your piezoelectric photo machine in the printing test process, there is a small number of broken lines occur, which is likely to be caused by the presence of bubbles in the photo machine cartridgeAlthough it will not cause a large print on the photo machineInfluence, but also to solve in time !

For example: at the beginning of the printing normal, after the occasional print break phenomenon; One color is lost when printing, usually black; Before printing, it is necessary to repeatedly clean the nozzle automatically in order to print normally.

The above problems are basically caused by the existence of bubbles in the ink cartridge, which mostly occurs in the daily use of the photo machine for more than half a year. A small amount of tiny air enters the ink cartridge through the photo machine nozzle, and gradually produces a small bubble phenomenon in the ink. The solution is to use a syringe to extract the ink with bubbles.

This operation can restore the ink supply system of your photo machine to normal. Use the tube head of the disposable syringe to insert the outlet where the ink cartridge is connected to the ink supply system. Tilt the syringe slightly and begin to slowly discharge the ink from the ink cartridge.

When the syringe tube is full, observe the number of bubbles in the extracted ink, and you can infer the situation of bubbles in the ink cartridge and the reason for the broken ink. The photo machine will not print out the bubbly ink, so it can only manually suck out the bubbles contained in the ink.

Then unscrew the lid of the corresponding ink bottle and inject the ink from the syringe into the ink bottle. After a few hours, the ink bubble will fuse into the ink and be used again. In this process, no ink is wasted and no cost is increased. If you observe that there are ink bubbles in the cartridge, repeat the previous operation to keep the cartridge free of bubbles.

The above is the solution of bubbles in the photo cartridge, I hope to help you!

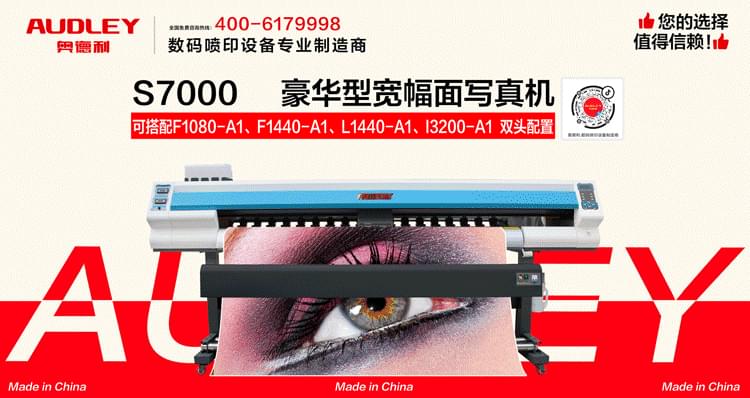

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.