Digital printing machine, as a professional printing equipment, has a wide range of applications in the printing field. In the actual production process, the production cost can not be underestimated, will directly affect the customer's income. So, how should we control the production cost of digital printing machine?

01

The nozzle is the core precision component of the digital printing machine. If it is not standardized and not paid attention to when used, the service life of the nozzle will be shortened, and the overall production cost of the digital printing machine will be increased. Therefore, the daily use specifications and daily maintenance of the digital printing machine nozzle are also a major factor in controlling production costs.

Daily use specifications:

Before printing out, the nozzle test strip should be printed first to ensure that the status diagram is normal and the spraying condition is good; At the end of printing, the nozzle must be completely close to the ink stack to ensure that the nozzle is always in a wet state.

Daily maintenance:

The nozzle is cleaned regularly by pumping ink to ensure that the nozzle nozzle is smooth. After the digital printing machine is printed every day, clean the dirty part of the whole machine, and then cover the dust cloth to prevent dust from entering the machine and blocking the spray hole.

02

The use of original high-quality matching ink, good ink and equipment complement each other, to achieve rich color, delicate picture printing effect. At the same time, a good digital printing machine ink color restoration degree is high, the amount of ink is controllable, there will not be a large area of strong color need to double the amount of ink. Although the price of the original ink will be relatively high, it can print more square pictures, and the whole is spread out evenly, compared with inferior low-cost ink, it is still very affordable.

03

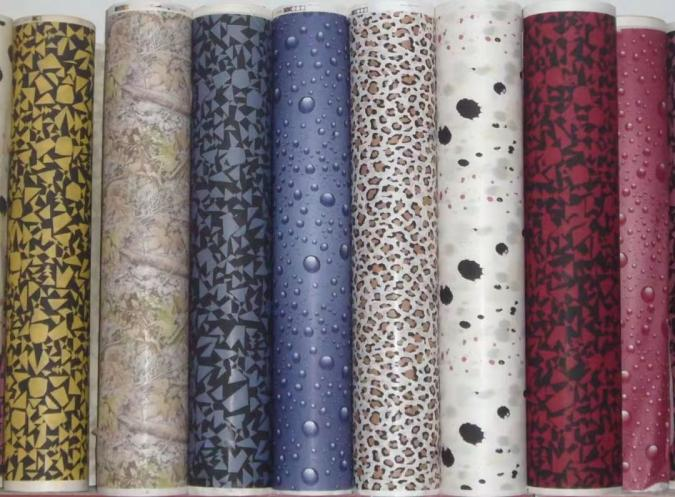

Printing media, as one of the two major consumables for digital printing machine printing, is a printing necessity that needs to be repeatedly purchased. At present, the thickness of the printing media on the market is different, and we do not need to choose the thickest material when using it, but to choose the appropriate material according to the color richness and resolution of the design screen. Select the appropriate material according to the actual situation of printing, which can not only meet the printing needs of users, but also reduce the production cost.

04

The longer the digital printing equipment is used, the lower the annual depreciation cost, and the less the annual production cost is spread equally. In other words, do a good job of maintenance of digital printing machine, extend the service life of digital printing machine, you can reduce production costs.

In addition to operating the equipment in accordance with the normal process, pay attention to the working environment of the equipment, such as temperature, humidity, dust and so on. Taking Flybutterfly digital printing machine as an example, the best temperature for work is15℃-30℃, humidity is35%-65%. In addition, pay attention to the dustproof work of the equipment, beware of dust entering the equipment and damaging accessories and electronic components.

05

The overall stability of the digital printing machine, the control of the production cost of the digital printing machine can not be ignored. If the digital printing machine frequently appears a variety of small faults and big problems, it not only needs to spend time and money to repair, but also slows down the printing progress of the order, which affects the income.

Audley digital printing machine accessories are made of high-end quality accessories, equipment performance is stable and reliable, quality is guaranteed, want to know more details, please call Audley service hotline:400-6179998; Or scan the QR code below:

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.