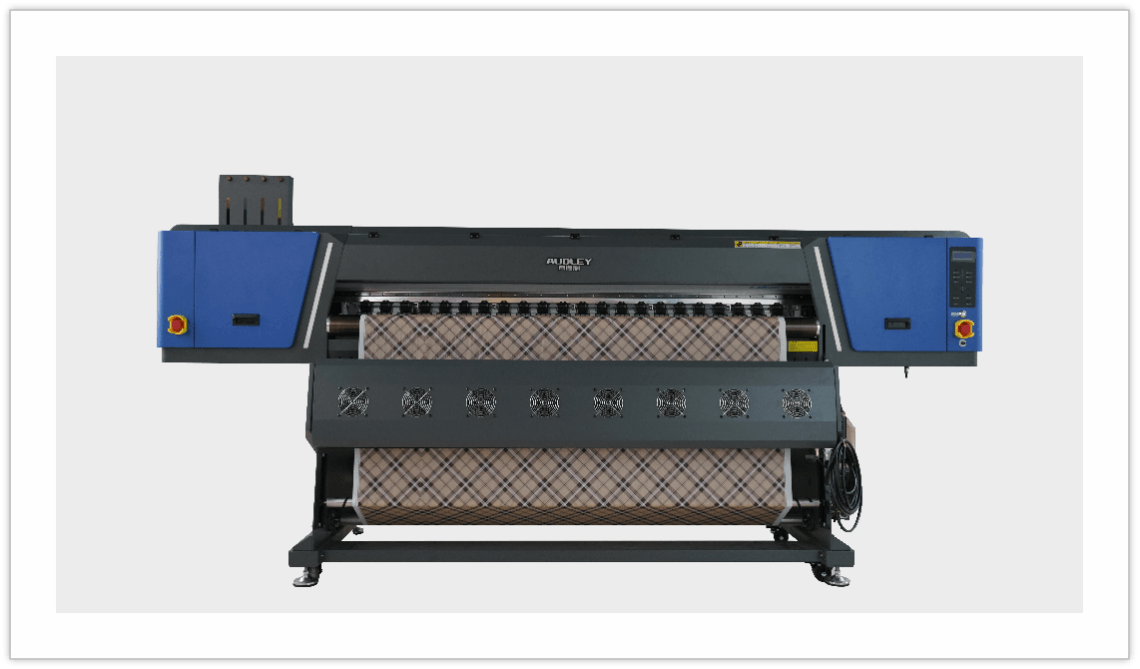

With the development of economy and the progress of society, people's requirements for the personalized and artistic living environment and textile printing continue to improve, a variety of new digital printing machines have appeared, and the development of digital printing technology is showing a trend of rising and blooming. Today, we bring you a brand new4Head digital printing machine Audley1904.

Recommendation reason

1. Sprinkler life

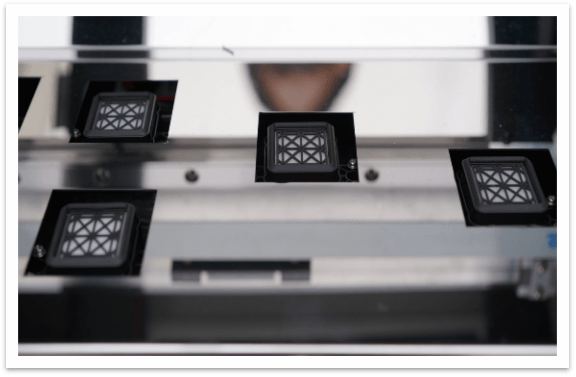

equip4An EpsonI3200-A1Sprinkler head,ALL MEMS(MEMs)The manufacturing process and the use of thin film piezoelectric elements make the high-precision nozzle arrangement possible, making the print head compact, fast, good quality and durable.

2. stability

Industrial grade all-aluminum frame: higher strength and smoother machine operation.

3. speed

4Branch nozzle,2pass:160square/Hour (s),4passThe printing speed is up to80square/Hour, top speed160square/Hour (s);1There are no more than one.

4. Print quality

Exclusive to EpsonMEMSThe precision nozzles and ink paths manufactured by the technology make the ejecting ink droplets close to the perfect circle and precise positioning.

Exclusive to EpsonVSDT(Variable ink drop technology)You can freely control the size of the jetted ink droplets, thus reducing the granularity of the picture, showing more picture details, smooth color transition, and high saturation.

The new nozzle dislocation arrangement solves the inconsistency between the left and right effects on the printing platform, and improves the printing quality at least20%.

5. Ease of operation

There is no need to make plates, print plates, repeat color and other complex processes, only need the operator to use the computer to deal with it, the operation is simple and convenient.

6. Energy consumption

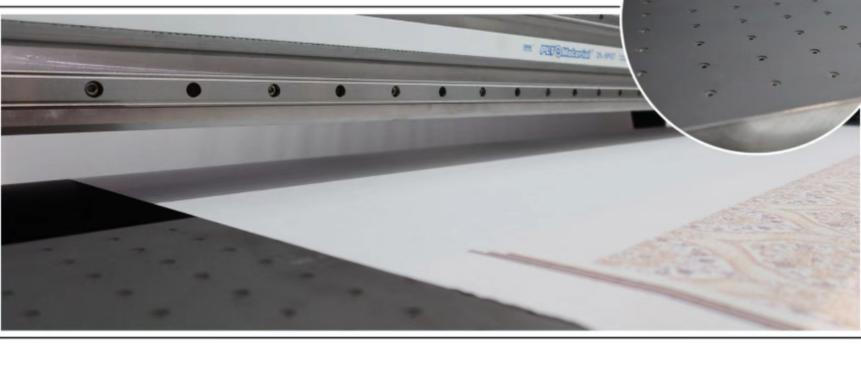

l Audley digital printing machine supports thin paper printing, allowing manufacturers to save costs and improve work efficiency.

l Optional rewinding system, flexible layout, maximize the use of paper area, reduce resource waste, save the cost of consumables consumption.

l Audley digital printing machine is equipped with an adjustable dryer, the manufacturer can adjust the power of the dryer according to the actual demand, saving unnecessary electricity consumption.

l The use of ultra-high concentration ink saves the amount of ink, the drying speed is faster, the required drying power is lower, and the production energy consumption is further reduced and the production cost is effectively reduced.

7. Labor cost

AudleyThe whole process of digital printing machine is controlled by computer, which reduces the intermediate links such as net making and pulp mixing, which is equal to reducing the number of workers and saving labor costs.

8.Sum up

Whether it is in the performance stability or production quality has a strong advantage, while in ink, energy consumption and material costs have all aspects of savings, greatly improve the production efficiency at the same time, greatly improve the competitiveness of the industry.

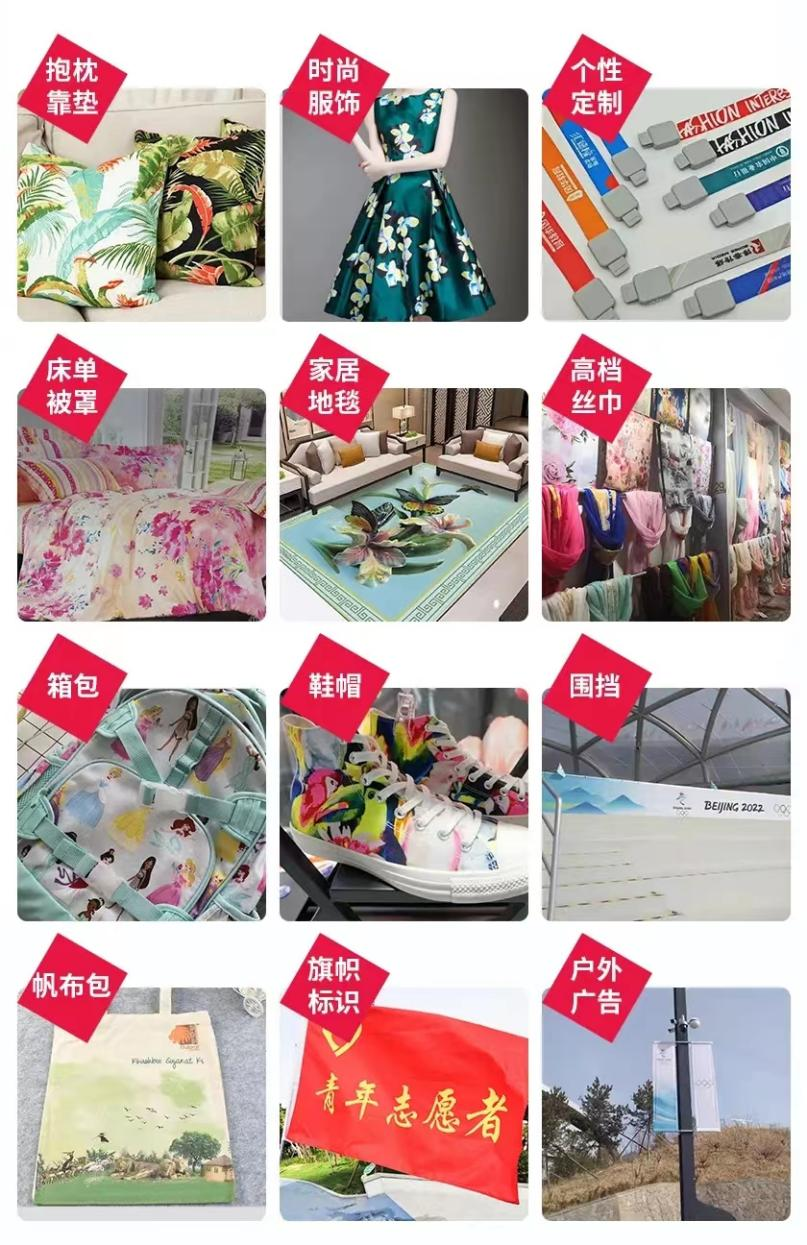

Application field

Applicable fields: clothing, home decoration, home textiles, advertising, etc.

Applicable fabrics: polyester, chemical fiber, chiffon, crepe de chine, polyester cotton, etc.

Audley as a senior digital printing equipment manufacturer, for different industries to develop a number of models, now have1.8Meter,2.2Meter,3.2Meters of different widthsDigital printing machineTo meet the diversified printing needs of customers.

For more information about the equipment, you can call the service hotline:400-6179998

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.