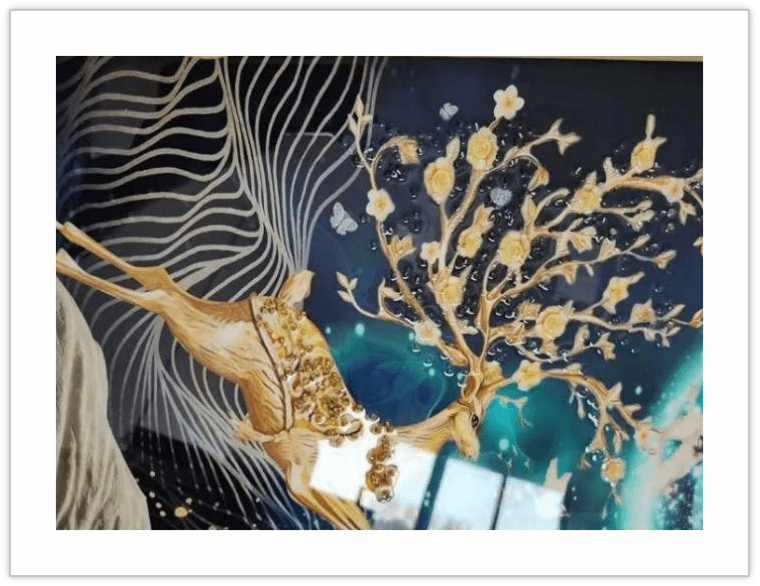

Crystal porcelain painting, with crystal-like crystal clear effect, stunning the public, rapid rise, become a popular in recent years. Do you want to know how such a beautiful crystal porcelain painting is made? Let me explain it to you.

The crystal porcelain painting uses the new hot melt technology and special equipment to hot melt the photo into the crystal material through a simple process, so that the painting and the crystal material are integrated, and the density board is tightly combined. No matter from a distance or close view, it can perfectly present the high-definition picture quality effect, and the picture is vivid and realistic.

1. Beautiful picture

2. Preservation resistance

3. Easy to clean

4. Insert bit

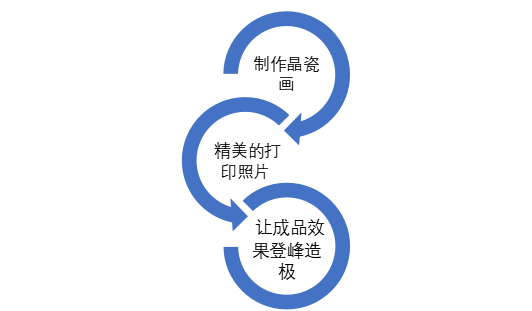

So, how is such a beautiful crystal porcelain painting made? Come and see!

passWide-format printerPrint the picture on photo paper orPPmaterially

Use a cold mount machine to attach the print to the back

Put the backplane affixed to the picture into the glue spraying machine for glue spraying to ensure that the picture is sprayed evenly

Manual drilling in the sprayed picture, in the appropriate position to sprinkle large diamonds, small diamonds, crystal porcelain, crystal shell, so that the picture more three-dimensional

Finally, the picture is put into the oven to cure and dry

Audley four color photo machine, ink color configurationCMYKPrinting, wide color gamut, vivid color, richer picture details, the overall effect is more exquisite, photo printing effect is easy to get.

AudleyADL5192Double head photo machineThe user really can:

1.Improve printing efficiency and productivity;

2.Save space, reduce rent investment;

3.Save labor, reduce wages, bonus benefits and insurance;

4.Save other operating costs;

Audley has been well received by advertisers since its launch two years ago. In order to bring a more comfortable printing experience to Audley users, if you want to know more, pay attention to Henan Audley.

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.