Epson nozzle has always been an important part of printing equipment such as photo machine, and a change will usher in the change of the printing industry. After Epson released the original "Zheng Pin head", Audley Digital follows the development trend of the industry, and the existing printing equipment is equipped with Epson original nozzle, which creates value for more customers with higher quality and better performance!

In this nozzle "expensive as gold" industry, the protection of the nozzle is more important, and more and more users understand the maintenance skills of the photo machine nozzle, in order to improve the work effect and reduce the cost of the nozzle. Photo machine nozzle is vulnerable to environmental changes and human operation to cause damage, in the use of time must pay attention to it, following the Audley Xiaobian together to understand the precautions of the photo machine nozzle !

Operating instructions (Please do the following)

1Before shutdown

①Shutdown control software②Turn off the main power switch③Ensure the normal return of the car, and ink stack close fit;

2Replace the ink stack core

①It is recommended to use the manufacturer's original ink stack core, which will not cause adverse effects caused by ink core deformation②Equipment placementMore than three days, use cleaning liquid to wash the ink stack core and waste ink tube to prevent ink clogging the tube;

3, stop printing

Do not plug and unplug with powerUSBPrint line, so as not to cause damage to the motherboard;

4After adding ink

Close the lid immediately after filling the ink bottle to prevent dust from entering;

Prepare in advancePlease follow the following protocol)

1Identify the manufacturer's ink logo, and use the original ink provided by the manufacturer to avoid affecting the print quality and after-sales maintenance;

2Photo machine has very high voltage stability requirements, it is recommended to configure the same or slightly larger specifications of voltage stabilizer, to protect the normal operation of the photo machine;

3When installing the photo machine, connect the ground wire to avoid electrostatic interference caused by dry air, static electricity of the human body and friction of the material surface, resulting in damage to precision electronic accessories and sprinkler heads.

Cleaning and maintenance (Please follow the following maintenance)

1The working room temperature of the photo machine is set in15-30Degrees Celsius, humidity at35%-65%In between, it is more favorable for photo machine nozzle printing;

2Clean the photo machine scraper regularly to prevent ink coagulation from affecting the nozzle;

3Keep the printing platform of the photo machine clean, regularly clean the ink, dust and foreign matter on it to prevent it from scratching the nozzle;

The above photo machinei3200-A1,F1440-A1And other series of sprinkler maintenance skills, I hope to help you!

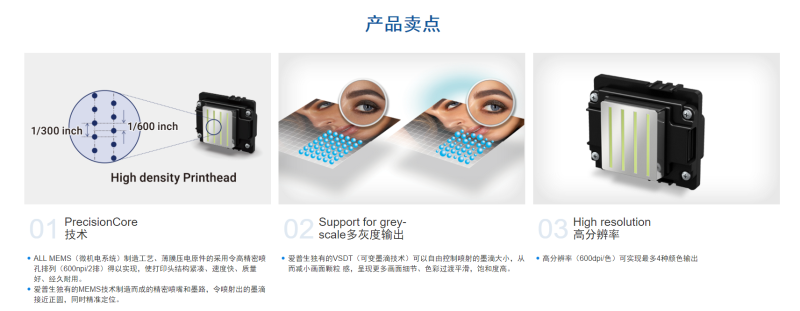

High speed sprinkler :I3200 high speed sprinkler, compatibility: weak solvent, water, thermal sublimation, UV Dual-head configuration: true high-speed printing, 75 square per hour; Control system: the most stable domestic board control system; Silent linear guide: imported silent linear guide, more stable machine movement 1 longer service life; Anti-scratch device: prevent the material from lifting the scratch nozzle, effectively protect the nozzle; Intelligent heating: Dual infrared heating: reduce drying time, speed up paper delivery efficiency, ensure high-speed printing; New frame design: mold appearance new aluminum alloy body structure design, effectively improve the picture printing quality; The height of the trolley frame adjustment: according to the thickness of the material, adjust the height of the nozzle, convenient for users to use more media; Silent linear guide: imported silent linear guide, more stable machine movement, longer service life;

1.With Epsoni3200-A1/E1Original authentic sprinkler head 2.Imported silent linear guide rail: no noise, more stable movement, more stable printing, extend the service life of the machine. 3.All aluminum lifting ink stack: automatic lifting ink stack, tighter sealing and long-term moisturizing, automatic cleaning Settings, cleaner and simpler printing. 4.German Igus chain, the movement is silent more stable. 5.Three speed adjustable press wheel, prevent static electricity does not fly ink, printing size is more accurate, no wrinkles.

With Epsoni3200-U1Nozzle, four-head configuration, high precision mode can be reached32㎡/h, production mode48㎡/h. Platform three zones adjustable suction, high power water coolingUVLights. Head automatic height measurement, anti-collision protection, nozzle independent constant temperature system. Heavy-duty pneumatic expansion shaft, rolling simple discharge system, large bearing weight, long service life, uniform retracting and discharging materials.